image courtesy of OnTraccr Technologies Inc.

The following article is sponsored by OnTraccr.Technologies Inc.

There’s no doubt that the construction industry has seen a large influx of new software hitting the market over the past few years. Many of those programs, however, mainly appeal to large contractors with an infrastructure built to support the addition of a cumbersome system, while most small to medium sized companies are left behind.

OnTraccr, a new productivity app for construction, is looking to make their software accessible to everyone, by making it as simple and easy to use as possible, while still giving your company the valuable data it needs to survive in our constantly changing industry.

Launched in February of 2021, OnTraccr is starting as a time-tracking app, but plans to expand to much more in the future. Building its foundation in time tracking is a great place to start, because labor is responsible for a substantial percentage of a business’ costs.

Having a real-time, electronically based time tracking system is not only good for business owners and managers, it’s also good for the hourly workers. Paper timecards take a lot of time to gather, sort through, and ultimately get people paid. That can not only reduce the accuracy of paychecks, but it can also put you behind on tracking project costs.

The construction industry has been in a tough job market for years, and easy and accurate time cards and timely paychecks can be a huge factor in retaining the staff that your company has.

How OnTraccr Works

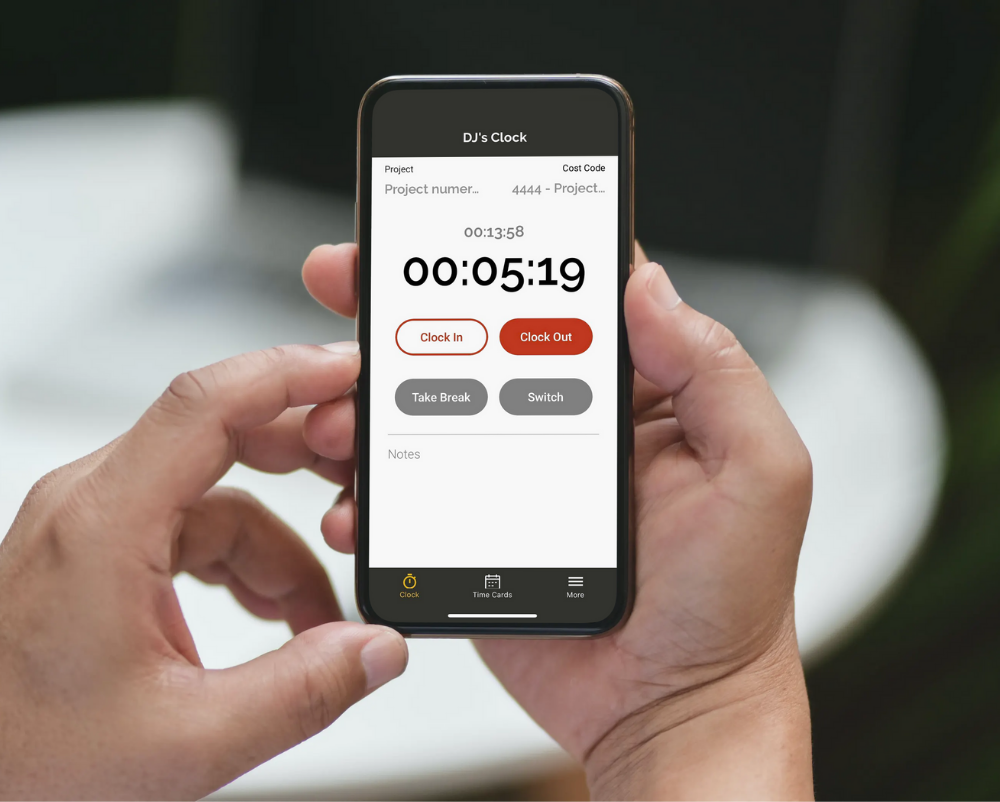

OnTraccr’s mission is to make technology accessible to everybody and their smartphone and web app design reflects that. The layout is clean, the buttons are large, and it avoids any unnecessary information that can lead to confusion.

Using OnTraccr as an Employee

Employees using the app to track their time are met with 4 clearly marked button options: clock in, clock out, take break, and switch (which allows the employee to change projects or job code). Doesn’t get much simpler than that. The time is then traced in real-time and able to be monitored by the management staff.

image courtesy of OnTraccr Technologies Inc.

Geofences or GPS locations can be established to ensure employees are in the correct location when they clock in and out. Companies can also log time manually or set up a “shared tablet mode,” allowing employees to clock-in using a 4-digit PIN in a centralized location.

Workers can review their time sheets though the app, make any necessary adjustments, and submit for approval when ready, making it easy to ensure they are paid the correct amount for the time worked.

Using OnTraccr as a Manager

Since time cards are tracked in real-time, management staff can perform budget tracking and job costing functions whenever they want. There are a variety of reports built into OnTraccr that contain valuable data, including:

-

Employee Payroll and Timesheets

-

Budget Tracking

-

Labor Productivity

-

Productivity Forecast

-

Project Timeline and Labor Curve

image courtesy of OnTraccr Technologies Inc.

Each report can be easily filtered by a variety of different categories, such as project, cost code, and approval status, allowing you to quickly find the data relevant to you. Report customizations can be saved for easy viewing later and exported to view, share, and analyze offline.

OnTraccr can even be integrated into QuickBooks or custom enterprise software, allowing payroll to be processed automatically when time cards are approved.

Future Developments

In addition to time tracking, OnTraccr plans to use their app as a means of team communication in the near future. Since the team will already need access to the software to log and view their time, it’s a natural next step to increase the app’s functionality. As an example, users will be able to create rooms based upon a specific topic, like RFI or safety conversations. These topic-based chats will keep everyone up to date, further connecting the field and office staff.

The company will also add billing and invoicing for time and material work and an integration into the popular project management software, Procore, as well.

Free Access

With its recent launch, the app is now available across the United States and Canada and the full version can be accessed for free, for life, for up to 4 team members. There’s no better way to find out if an app will work for your team than to see exactly how it works before committing to it.

Above and beyond the first 4 users, pricing is very straightforward at $9.99 per month per additional user. For enterprises with a large number of users, you can contact their sales team for a cost estimate.

The app is available on both Android and Apple devices and the web app can be accessed through any internet browser.

source https://www.constructionjunkie.com/blog/2021/2/26/ontraccr-is-making-construction-technology-accessible-to-all